Our products

PROPELLERS

Ratier-Figeac is a leading supplier of propeller systems for turboprop aircraft worldwide. It first began to produce propellers in the 1900s.

Today Collins Aerospace develops, certifies and manufactures high power composite propellers for a range of engines from 2,000 to 11,000 hp, for the main manufacturers: US Navy, US Air Force, French, British and German Armies, ATR, Xian, Airbus Defense & Space, De Havilland. More than 350 companies use its propellers.

Ratier-Figeac is the Collins Aerospace Center of Excellence, manufacturing the main components of propeller systems, notably blades and hubs. Developments are implemented in synergy with Collins Aerospace. An internal research team designs the system and carries out all of the qualification and certification tests. Ratier-Figeac manages developments for European programs.

Its technology has evolved over the years to the use of innovative composite blades, as well as electronic propeller controls. A new eight-blade propeller (NP2000) has recently been commissioned on the Hawkeye E-2C (United States and International Navies) as well as the Hercules C-130H aircraft; note also the propeller system of the Airbus A400M transport aircraft, with a diameter of 5.3m and a power of 10 700 HP.

COCKPIT AND CABIN

Ratier-Figeac is the centre of excellence for electrical flight controls (mini-handles, throttle, rudder pedals) and cabin equipment (door dampers, propeller brakes and rotor brakes).

The company has nearly 40 years of experience in cockpit equipment that it develops in close collaboration with test pilots and airline pilots. More than 12,000 aircraft are flying today with its equipment around the world. Ratier-Figeac’s experience, new development and innovation allow it to offer a complete Pilot/Aircraft interface for all segments of the aviation market from civil aircraft to military aircraft and EVTOL.

Ratier-Figeac’s throttle levers and mini-stick controllers equip a large number of Airbus, Bombardier and Dassault cockpits.

The door dampers have accumulated more than 750 million hours of flight time on the Airbus and Embraer fleets, and the propeller and rotor brakes have achieved more than 13 million braking cycles on the ATR, C295, Airbus Helicopters and Leonardo Helicopters applications.

The teams are currently developing the complete cockpit equipment for the Comac C919 and Lilium Jet, as well as the door dampers for the Comac C919 and the Airbus A220.

DOOR DAMPERS

They perform two functions: In normal operation, they serve to dampen the door by a hydraulic part. In an emergency, the pneumatic part opens the door.

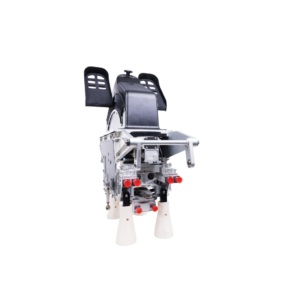

RUDDER PEDAL

The rudder pedal is the primary flight control that is controlled by foot. It enables the pilot to control the aircraft around its yaw axis. When the pilot presses one of the rudder pedals, the pressure applied is transmitted to the rudder via electric and/or hydraulic flight controls or cable. Upon landing, its function by simultaneously pressing both pedals, enables activation of the landing gear brakes.

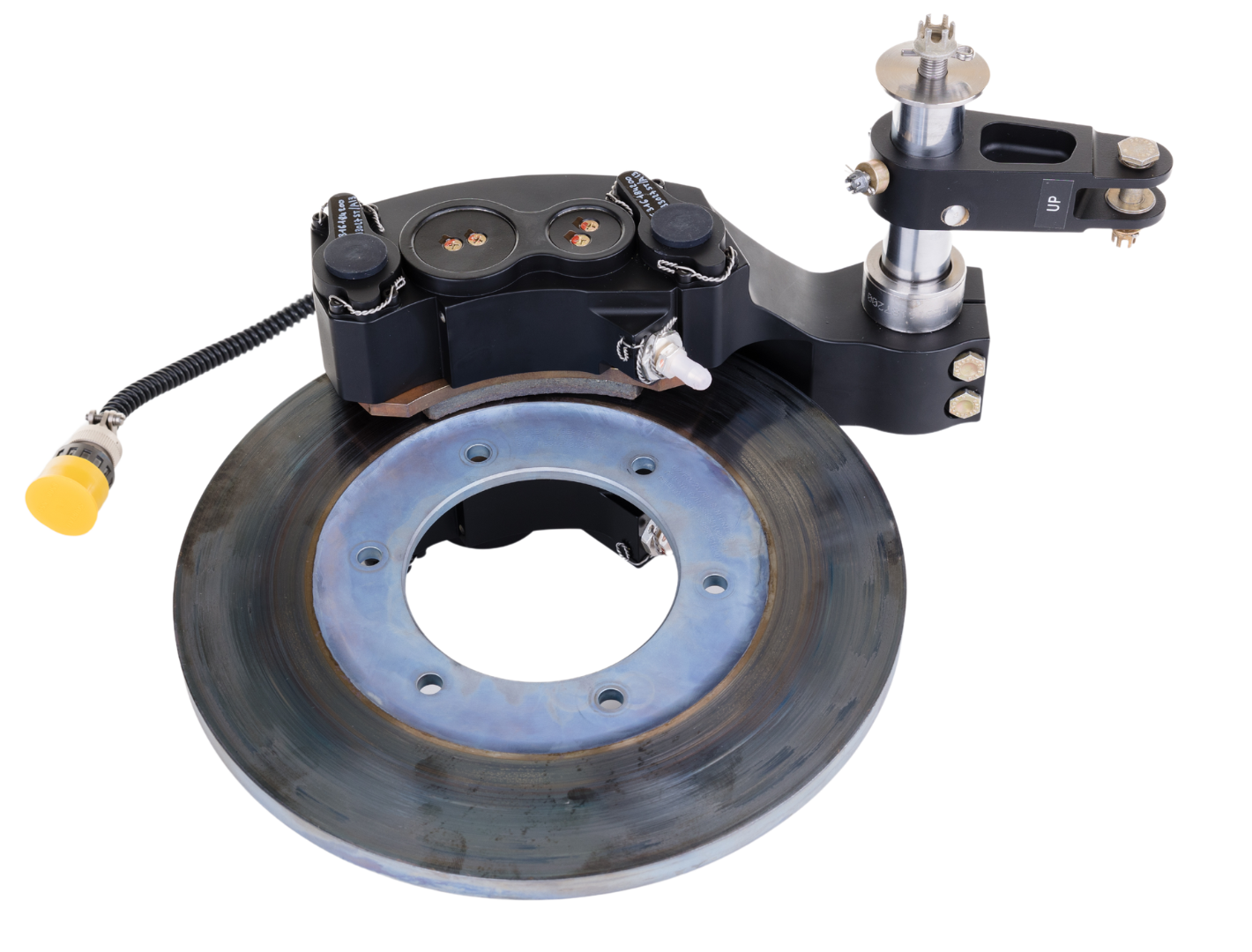

BRAKES

- Propeller brakes: They are installed on turboprops. Their main role is to allow the engine to run at idle, without the propeller turning, to replace the APU (Auxiliary Power Unit).

- Rotor brakes: Its main function is to stop the rotor after the helicopter has landed and the engines have stopped. Some features allow the engine to be kept at a minimum rpm in order to board or disembark passengers more quickly.

THROTTLE LEVERS

The throttle lever controls the engine thrust, and thrust inversion. Its modern versions integrate the engine shut-down, rapid go-around, and motorization disconnection functions.

SIDE STICKS

The side control column is an electromechanical assembly controlling the aircraft in roll and depth, via aerodynamic surfaces located on the wing. A new generation of sleeves, called "active", makes it possible to electrically pair the pilot and co-pilot sleeves, but also to return to the pilots forces and positions according to the flight situation.

COCKPIT AND CABIN

Ratier-Figeac is the centre of excellence for electrical flight controls (mini-handles, throttle, rudder pedals) and cabin equipment (door dampers, propeller brakes and rotor brakes).

The company has nearly 40 years of experience in cockpit equipment that it develops in close collaboration with test pilots and airline pilots. More than 12,000 aircraft are flying today with its equipment around the world. Ratier-Figeac’s experience, new development and innovation allow it to offer a complete Pilot/Aircraft interface for all segments of the aviation market from civil aircraft to military aircraft and EVTOL.

Ratier-Figeac’s throttle levers and mini-stick controllers equip a large number of Airbus, Bombardier and Dassault cockpits.

The door dampers have accumulated more than 750 million hours of flight time on the Airbus and Embraer fleets, and the propeller and rotor brakes have achieved more than 13 million braking cycles on the ATR, C295, Airbus Helicopters and Leonardo Helicopters applications.

Les équipes développent actuellement les équipements du cockpit complet du Comac C919 et du Lilium Jet, ainsi que les amortisseurs de portes du Comac C919 et de l’Airbus A220.

THROTTLE LEVERS

The throttle lever controls the engine thrust, and thrust inversion. Its modern versions integrate the engine shut-down, rapid go-around, and motorization disconnection functions.

verins de portes

They perform two functions: In normal operation, they serve to dampen the door by a hydraulic part. In an emergency, the pneumatic part opens the door.

SIDE STICKS

The side control column is an electromechanical assembly controlling the aircraft in roll and depth, via aerodynamic surfaces located on the wing. A new generation of sleeves, called "active", makes it possible to electrically pair the pilot and co-pilot sleeves, but also to return to the pilots forces and positions according to the flight situation.

RUDDER PEDAL

The rudder pedal is the primary flight control that is controlled by foot. It enables the pilot to control the aircraft around its yaw axis. When the pilot presses one of the rudder pedals, the pressure applied is transmitted to the rudder via electric and/or hydraulic flight controls or cable. Upon landing, its function by simultaneously pressing both pedals, enables activation of the landing gear brakes.

BRAKES

- Propeller brakes: They are installed on turboprops. Their main role is to allow the engine to run at idle, without the propeller turning, to replace the APU (Auxiliary Power Unit).

- Freins de Rotor :

Sa fonction principale est de stopper le rotor après l'atterrissage de l'hélicoptère et l'arrêt des moteurs. Certaines fonctions permettent de garder le moteur à un régime minimum afin d’embarquer ou de débarquer les passager plus rapidement.

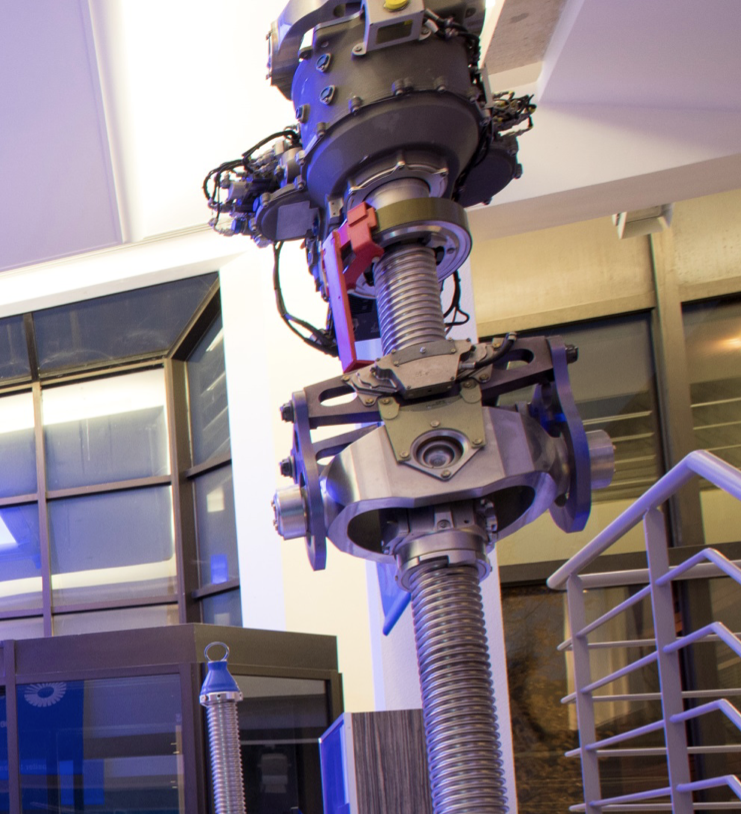

THSA

Ratier-Figeac designs, produces and markets high-tech products and ensures the complete integration of systems for its customers.

Ratier-Figeac has a wealth of experience in the design and manufacture of trimmable horizontal stabilizer actuators (THSA).

The THSA provides the structural link between the horizontal plane and the aircraft’s empennage. It allows the horizontal plane to be moved to control the impact of the aircraft and optimize flight performance.

Our complete systems equip the Airbus A380, the A400M. A recent development concerns the Boeing B777X.

HELICOPTER PARTS

MAIN ROTOR MAST

This lifts, controls and propels the helicopter. It must allow rotation of the blades, flapping joints, drag joints, and feathering joints.

MAIN TRANSMISSION BOX

This is a mechanical assembly used to transmit engine power to the main rotor mast, transmit the angle between the engine power take-off and rotor shaft, and supply the accessories (hydraulic pump, alternator, rotor brake, etc.).

TRANSMISSION ROD

This transmits power from the main gearbox (MGB) to the tail rotor shaft.